Turn Your Steam and Waste Heat into Savings: Simple, Sustainable, and Cost-Effective

ABOUT WES

At WES, we innovate for a sustainable tomorrow. Our tech cuts energy costs and carbon footprints. Let's build a smarter, greener future together.Explore

Connect

Share your goals; we'll show how to optimize your steam for savings and efficiency.

Plan

Get a simple, personalized plan outlining costs, savings, and site visit specifics.

Transform

Implement our solution swiftly, reduce costs, and boost efficiency and sustainability.Green Genie

Green Genie is a smart digital tool by Wankel Energy Systems that helps factories save energy and cut emissions. It shows live data on energy use, predicts maintenance needs, and tracks savings—making sustainability easy to understand, measure, and improve.

LATEST NEWS

Wankel Energy Systems Triumphs at EnVision 2023

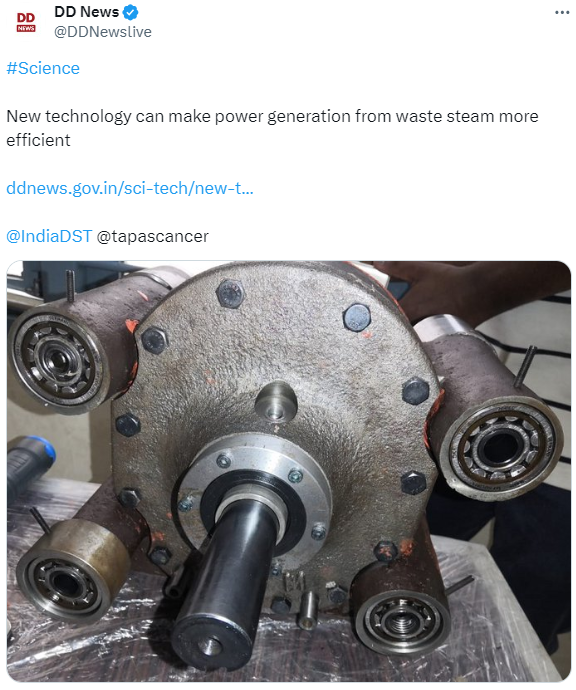

Wankel Energy Systems Triumphs at EnVision 2023 IIT Madras Unveils Sustainable Steam Expander Technology

IIT Madras Unveils Sustainable Steam Expander Technology IIT Madras' Leap Towards Efficient Industrial Energy

IIT Madras' Leap Towards Efficient Industrial Energy WES enters as finalists in MIT Climate & Energy Challenge

WES enters as finalists in MIT Climate & Energy ChallengeWE ARE HERE FOR YOU

Ready to transform your steam into savings? Take control and estimate your potential savings and energy recovery with our 'Green Genie' — your advanced energy savings calculator.Registered Address

IIT Madras Research Park, 01 FA, 1ST Floor, Kanagam Road, TTTI Taramani, Chennai 600113Lab Address

FMB 121, EnERG Lab Department of Applied Mechanics Indian Institute of Technology Madras Chennai 600036Get in Touch

9am-6pm

wes@wankel.in

wankelenergysystems

Copyright © 2025 WES | Powered by WES